Or you may research some other potential partners, who can provide you with a better price (whilst supplying you with equally good materials). In fact, you already know that labor costs can spiral out of control if you don’t meticulously monitor them. Another commonly used term for manufacturing costs is product costs, which also refer to the costs of manufacturing a product. Here are some frequently asked questions (FAQs) and answers that address key concepts related to manufacturing costs.

- You must set a finite period during which you calculate the total manufacturing costs.

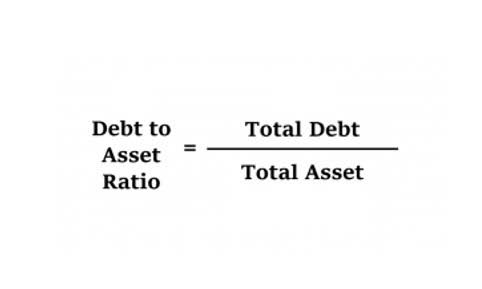

- Keep reading to learn how to calculate total manufacturing cost, how to use the formula, and why it matters.

- Hence, he suggests that top-level management increase the sales price of chairs.

- Simultaneously, the managers can reduce the indirect manufacturing overheads by saving on utilities.

Benefit #4: Assists in “make or buy” decisions

In order to gain this insight, your organization will need to have visibility into end-to-end spending. Calculating the cost of goods manufactured helps businesses determine the total cost incurred in producing goods ready for sale, aiding in pricing decisions and financial reporting. Direct labor refers to employees total manufacturing cost formula directly involved in production tasks, while indirect labor includes employees who support production indirectly, such as supervisors and maintenance personnel.

Total Manufacturing Cost: Formula, Guide, & How to Calculate

This means that the project has incurred $95,000 in actual costs for the work performed so far. When production increases, these costs rise, and when production decreases, these costs go down. Cloud solutions enable you to work Airbnb Accounting and Bookkeeping from anywhere, at any time, meaning you shouldn’t miss a trick when it comes to spend. But remote access aside, Manufacturing software’s real strength comes from the fact that it unites all your business functions, allowing every employee to complete work within the same system. A fine balance must be struck, in terms of setting a price that falls within the market norm, but also retrieves an acceptable return (based on the investment that went into producing each good). Optimize your workforce, take control of inefficiencies, and watch your profits soar with team time tracking software.

Actual Cost of Work Performed (ACWP): Meaning, Calculation & Role

- Direct labor refers to the wages, benefits, and payroll taxes paid to employees directly involved in the manufacturing process.

- Learn how Cin7’s all-in-one inventory management software can help your business.

- As a manufacturer, knowing the total cost of manufacturing isn’t just a “nice-to-have” — it’s something you absolutely need to know.

- Gone is the need to monitor stock levels and calculate potential output– inFlow does it all instead.

- To identify direct labor costs, you need to separate employees who play a direct role in the production line.

- Indirect material costs include items such as containers or pallets used to store raw materials safely.

- Indirect costs are not directly related to manufacturing and, therefore, generally remain the same period over period.

This calculation provides insight into how much it costs to make your product, identifying any underlying inefficiencies or exorbitant expenses. Once you identify the indirect costs, you must choose an allocation method to distribute these costs to products. Machine hours measure how much machine time is used for production, while labor hours focus on the time employees spend in production.

Any unfinished products or work in progress (WIP) inventory is not included in the COGM calculation. However, in cases where all materials are used, assets = liabilities + equity the COGM and total manufacturing cost would be the same. Direct costs change based on the production period and how much product you manufacture. This generally includes materials and labor, which vary based on many factors, such as demand planning and staffing.Wondering how to calculate direct materials cost?

Benefit #1: Assists in cost control

This can help you see if you’re underestimating or overestimating your production costs, allowing you to make better decisions moving forward. By using Brahmin Solutions, you can automate the process of calculating and tracking your manufacturing costs, saving time, reducing errors, and ultimately boosting your bottom line. Direct labor refers to the wages paid to the workers who are hands-on in creating your product.